![]() Building C, Yida Zhigu, Yantai Development Zone, Shandong, China

Building C, Yida Zhigu, Yantai Development Zone, Shandong, China

![]() +86 535-2160556

+86 535-2160556

![]() +86 13355351666

+86 13355351666

![]() shandongnafiber@163.com

shandongnafiber@163.com

Follow us

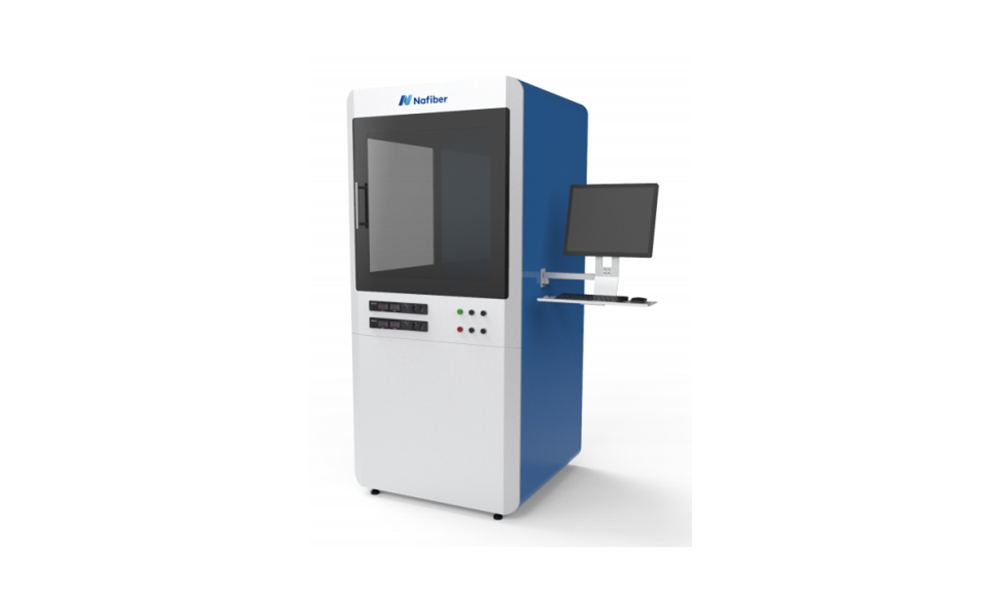

Product characteristics:

1、Multifunctional, High voltage, High precision,High stability

2、Wide range of material applications, with switch able direct writing and spinning functions

3、High precision motion mechanism, fully automatic control

4、Multiple types of melt and solution nozzles with wide temperature control range

5、Eficient temperature and humidity environmental control

6、Equipped with online observation and video recording functions7、Modular and customizable functions

Strong R&D strength

Senior Nanomaterial Expert

Excellent technical engineer

Strategic cooperation among universities

Wide range of product applications

Product characteristics:

1、Multifunctional, High voltage, High precision,High stability

2、Wide range of material applications, with switch able direct writing and spinning functions

3、High precision motion mechanism, fully automatic control

4、Multiple types of melt and solution nozzles with wide temperature control range

5、Eficient temperature and humidity environmental control

6、Equipped with online observation and video recording functions

7、Modular and customizable functions

Product advantages:

1、Fully enclosed experimental environment with constant temperature, humidity, and airflow

2、Imported module motion unit, high-precision fully automatic control, dynamically adjust able parameters (such as distance, liquid supply speed, temperature, humidity, etc) during the experiment

3、Good human-computer interaction system, custom variable control, easy to operate

4、High system integration, full parameter feedback, saving, exporting, and calling

5、Multiple types of customizable spinning collectors and nozzles to meet various scientific research needs

6、Safety protection: power overvoltage and overcurrent protection, working operation indicator light, emergency stop switch, door opening and power outage, limitalarm, etc

Technical Data:

| Overall dimension | 800(L)×750(D)×1700(H)(mm) Material: Sheet metal and painting |

High voltage | 1. Positive polarity:0-30 kV,Current:0-1mA 2. Negative polarity:0-30 kV,Current:0-1 mA · Equipped with electric shock and power outage protection · High voltage, High stabilty, High accuracy |

Mett directwriting | 1.Melting nozzle: Heating temperature:room temperature-400℃,nozzle can be selected for different heating ranges. 2. Feeding module: pneumatic feeding, with high-precision pressure regulating valve to adjust the pressure, and air pressure adjustable from 0.01to 0.8Mpa;MaXimum flow rate 40L/min; · Multiple needle sizes available, capable of achieving 0.5-50 μ M Single fiber direct writing · The stainless steel cylinderis easy to clean and can be reused |

Solution direct writing Electrospinning | 1.Solution supply module: high-precision liquid pump:0.0001mm/s-0.5mm/s, continuously adjustable, suitable for solution direct writing and Electrospinning 2. Special needle for solution direct writing,with a diameter of 1-100 micrometers available, capable of achieving 0.5-20 μ M Single fiber direct writing 3. Electrospinning multi type nozzles: single needle, multi needle, coaxial needle, etc · Needle positioning and correction function |

Automatic motion control system | 1.X axis(automatic positioning): 0-350mm 2.Z axis(automatic positioning):0-350mm 3.Y-axis(automatic reciprocation): Reciprocation 0-80mm ·X-Y axis motion speed 0-300mm/s, positioning accuracy≤1μM ·Z-axis motion speed 0-80mm/s, positioning accuracy≤5μM |

Collector system | 1. Direct write receiving platform Conductive glass receiving platform,collection range 150mmX150mm 2. Rotary drum collector Drum diameter:100mm; Drum length:210mm; Drum speed:0-1500rpm 3. Plate collector:200mm×200mm · Multi mode receiver: cage type, disc type, tube type, hydrogel fiber collector, etc · Customizable |

Temperature and humidity control system | 1.Temperature control: Spinning area temperature-70℃,Accuracy±1℃ 2. Humidity control:30%-80%,Accuracy 3% 3.Exhaust gas removal control: 500-5000 sccm 4. Efficient dehumidification device 5. Spinning chamber atmosphere control |

Operating system | 1.Capacitive touch human-machine interface for setting and displayingwork data 2. Window precise control system, experimental data can be saved, queried, and called 3. Realize automatic control of XYZ axis and liquid supply device 4.Custom variable control, customizable trajectory settings |

| Observation system | 1.LED spinning lighting,capable of observing the spinning process,with adjustable lighting position 2. Equipped with a high-definition microscope camera, with an adjustable observation magnification of50-500 times, and online observation and video recording functions ·Suitable for all melt and solution nozzles |

Safety protection system | Power overvoltage protection,power overcurrent protection, working operation indi-cator light,emergency stop switch,door opening and power outage, limit alarm,ete |