![]() Building C, Yida Zhigu, Yantai Development Zone, Shandong, China

Building C, Yida Zhigu, Yantai Development Zone, Shandong, China

![]() +86 535-2160556

+86 535-2160556

![]() +86 13355351666

+86 13355351666

![]() shandongnafiber@163.com

shandongnafiber@163.com

Follow us

Product characteristics:

1、Simple design, savelaboratory space

2、Simple operation, easyto start

3、External power supply connection, more convenient operation

4、Expandable yarn spinning module

5、Functions can be customized

Strong R&D strength

Senior Nanomaterial Expert

Excellent technical engineer

Strategic cooperation among universities

Wide range of product applications

Product characteristics:

1、Simple design, savelaboratory space

2、Simple operation, easyto start

3、External power supply connection, more convenient operation

4、Expandable yarn spinning module

5、Functions can be customized

Product advantages:

1、Spinning chamber space is large, Equipmentvolume is small, Saving laboratory space

2、High degree of customization,which can achieve customization of high-voltage power supply, liquid pushing device, spinningcollector, and spinning nozzle to meet various e-xperimental needs

3、External high-voltage power supply to avoid interference, making spinning more stable

4、Safety protection: power overvoltage and overcurrent protection, working operation in dic-ator light, emergency stop switch, dooropening and power outage, limit alarm, etc

5、Can be spun in multiple solutions to meet basic spinning test requirements

6、CNC color touch screen system, experimental data can be saved, queried, and called up

Technical Data:

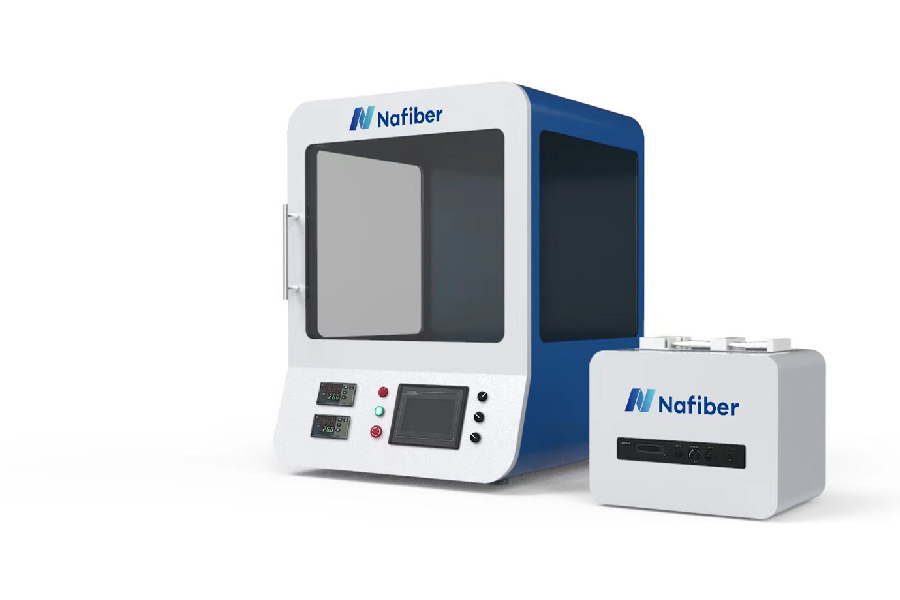

| Overall dimension | Main body:700(L)×760(D)×900(H)(mm) Accesory body:400(L)×350(D)×260(H)(mm) Material: Sheet metal and painting |

High voltage | 1.Positive polarity:0-30 kV,Current:0-1 mA · Equipped with electric shock and power outage protection · High stability, High precision, Small volume |

Motion control system | 1.X axis(manual positioning):0-190mm 2.Z axis(manual positioning):0-120mm 3.Y-axis (automatic reciprocation): 0-300mm 4. Distance from Spinneret to collector: 10-240mm · Range accuracy≤0.01mm |

Liquid supply system | 1.Feed rate of syringe pumps: 0.0001mm/s-0.5mm/s 2. One syringe pump: Dual path 3.The syringe pumps are placed outside: PTFE hose is needed to connect the pump to the spinneret 4.Multi-ype spinneret:Singlespinneret,multiple spinneret, coaxialspinneret, side by side spinneret, parallel spinneret,etc |

Collector system | 1.Rotary drum collector:Drum diameter.60mm; Drum length:210mm; Drum speed:0-1000rpm · Multi-style collector, customizable |

Temperature and humidity controlsystem | 1.Temperature control Spinning area temperature-60℃,Accuracy ±1℃ 2.Exhaust gas removal control:500-5000 sccm 3.Integrated temperature and humiditysensor, temperature and humidity displayed on the screen and panel |

Operating system | 1. PLC system of full parameter feedback, saving, exporting, and calling 2.Remote control function of mobile terminal 3.7 inch touch human-machine interface with high integration level 4.Formula interface allowsfor one click import ofexperimental parameters to achieve one click spinning |

| Observation system | 1.LED lighting: The spinning process can be observed 2.Thelighting postion is adjustable |

Safety protection system | Indicator ight,emergency stop switch,open door power of,limitalarm,grounding protection,etc |